NEW Industrial Air Treatment Package

Available Options

- -94° F Dew Point Rating

- Additional Carbon Filter

- NEMA4 Control Panel

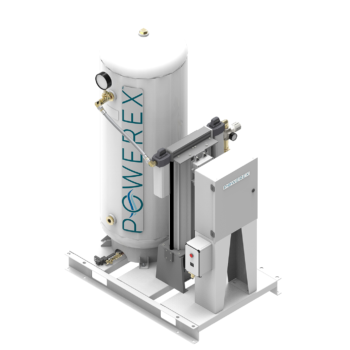

Powerex is thrilled to introduce the TDD Industrial Air Treatment Skid! This brand-new product was designed by our in-house engineering team to provide clean and dry compressed air at a low dew point rated for -40° F. The TDD package is ideal for critical process applications requiring moisture-free compressed air such as instrument air systems, food packaging and processing applications to prevent contamination and spoilage, and pharmaceutical manufacturing where dry compressed air is vital to maintain high purity and quality.

Air Purification Package Features & Benefits

The air purification package shall consist of the following: desiccant air dryer, filtration, dew point monitor with visual and audio alarms, pressure regulator, and a NEMA1 control panel for a single point electrical connection. All components shall be skid mounted and piped to the air receiver.

The system shall include an internally lined ASME air receiver rated for 200 PSI MAWP. The tank shall be equipped with a pressure gauge, safety relief valve, and electronic automatic drain.

The standard twin-tower, heatless desiccant air dryer is designed for a pressure dew point of -40° F, sized to meet the full SCFM requirement of the system. The dryer shall be installed and plumbed on a common steel skid to the air receiver. The dryer design shall be of the automatic pressure swing, heatless, regenerative type and shall include a solid-state cycle timer, reliable switching valve design, and purge muffler for quiet operation.

The filtration system shall consist of 2 stages of filtration mounted and plumbed to the air dryer. The first stage of filtration shall include a .01-micron or finer pre-filter with element change indicator and automatic condensate drain and installed upstream of the air dryer. The second stage shall include a 1-micron particulate filter with element change indicator installed downstream of the air dryer.

Additionally, each assembly shall include a pressure reducing valve with a pressure gauge that shall be installed downstream of the final filter to allow for field adjustable outlet pressure.